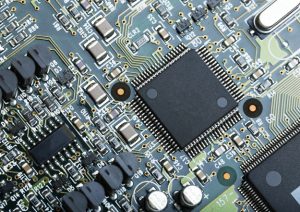

Printed circuit board assembly (PCBA) is a manufacturing process for assembling printed circuit boards (PCBs).

It is a process that joins electronic components to a PCB, usually with solder.

The term “printed circuit board” refers to a board that has copper traces on it which are etched so that they form connections between points on the board. The copper traces are then connected to components by soldering them into place on the board.

In the PCB assembly process, the PCB has holes or pads that correspond to the component lead positions. The components are inserted into these holes and soldered in place. This process may be done by hand or by machine.

The most common manufacturing process for PCBAs involves pick-and-place machines which feed components to the operator who places them onto the board using tweezers and/or vacuum pick-up tools. The operator then heats each component using a soldering iron to reflow the solder joints, thereby bonding the component to the board. A stencil can be used to apply solder paste onto pads before placing components on top of it.

They are used in most electronic devices, including computers, telephones and other information technology equipment.

Its main purpose is to connect all of the components that make up an electronic device as efficiently as possible. This reduces the amount of space required for each component by allowing them to be placed closer together physically while still remaining electrically isolated from one another (so they can’t interfere with each other). This also reduces the amount of wiring needed by allowing signals between components to be carried over short distances rather than having separate wires run between them.

Different methods for PCBA include:

There are many methods of printed circuit board (PCB) assembly. Each has pros and cons, depending on the application. For example, the cost is not always the most important factor in the selection process. Some applications require a higher level of reliability than others.

Let’s walk through some major assembly methods:

Thru-hole technology (THT) – This involves holes drilled through the board and soldering parts on both sides.

Surface mount technology (SMT) – This involves placing parts on pads or lands on the surface of the board The process is much quicker and requires less labor, but surface mount components are generally smaller and more expensive than through-hole components.

Mixed technology – As the name indicates, mixed technology includes properties of SMT and THT.

Tips on picking the right assembly provider

Printed circuit boards (PCBs) are electronic circuits that are manufactured by the PCB assembly company. They are used for a wide variety of electronic products, ranging from simple to complex. The process of building a PCB is quite involved and requires many different components. These materials can be obtained from several different vendors, each offering something slightly different from the other.

After you have selected the vendor that meets your needs and wants, it is time to start the PCB assembly process. This is where you will need to look at the various features they offer and decide which ones best meet your needs.

When selecting a PCBA company, there are many factors that need to be considered before making a final decision on who will do the work for you. For example:

- What type of equipment does the manufacturer use?

- What type of technology do they implement in their manufacturing processes?

- How much experience do they carry in this field?

- What kind of qualifications do they have?

- Do they have any certifications or awards?

These questions should be answered before making any final decisions on who will build your printed circuit boards because it could make all the difference between having them done correctly or having them done improperly…or even incorrectly!